How does laser cleaning work?

Laser cleaners work by heating the surface layer of an item, basically burning the rust or paint off.

Laser cleaners work by heating the surface layer of an item, basically burning the rust or paint off.

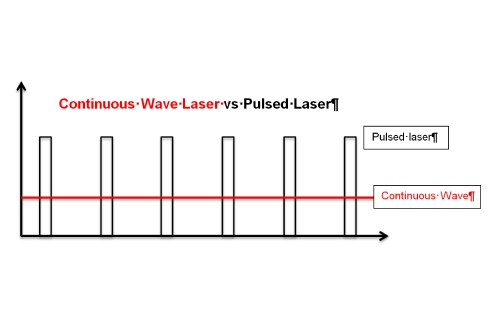

There are two main types of laser cleaners: Continuous Wave laser cleaners and Pulsed laser cleaners. Continuous Wave has the lowest cost and most power. Pulsed laser cleaners have least power and most finesse, but are most expensive.

Pulsed laser uses pulses of laser energy to clean. These pulses have high energy but overall the power is less, typical a few hundred Watts. Think of it like a flock of woodpeckers! Pulsed is generally best for paint or sensitive surfaces. Continuous wave is the big gun in laser cleaning, and uses continuous raw power to quickly burn the contaminants off. However the high amount of heat can partially melt the surface if overdone. On thin panels this much heat can cause shrinkage distortion in the steel.

Laser cleaners are perfect for cleaning metals, as the contaminants burn off without damaging the metal substrate. They can also be used on most types of stone. In general, pulsed lasers cause minimal damage to the substrate. Continuous wave lasers are more powerful but more damaging to the base material being cleaned. Laser cleaners remove rust, paint, oil and oxides from all metallicl and some non metallic surfaces. Carbon black absorbs fibre laser energy strongly, allowing quick cleaning of black ash, carbon deposits and oil stains. Lasers are commonly used to clean tyre moulds of rubber build up, as tyre rubber contains high amounts of carbon black.

Pulsed lasers are the best at protecting the base material, but also the most expensive, costing around $20,000 upwards depending on power level.

Constant Wave (CW) lasers are cheapest and most powerful, but also have the least finesse.

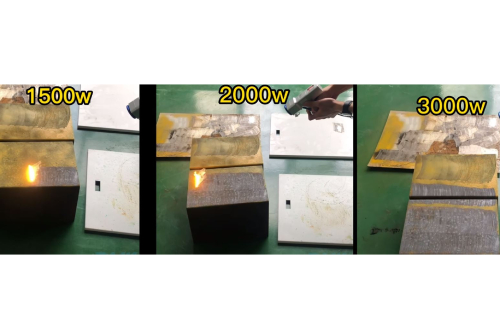

Thin contaminants can be removed quite quickly, but the thick layers take much longer. For thin layers a 1500W CW laser can clean up to 20 square metres per hour. Pulsed lasers around 200W are about half the speed (depending) but are gentle to the substrate being cleaned.

Same as for laser welding, eye protection for the laser cleaner user and anyone in the area is critical (see our page on laser safety). While laser welders produce welding fumes like TIG or MIG, requiring some level of lung protection, laser cleaners put all their energy into burning materials. As such, they require high levels of protection from fumes and the chemicals generated during cleaning.