Laser welders for sale

Our range of laser welders covers all types of handheld laser welding.

Laser Welders

Laser Welders

Laser Welders

Laser Welders

Our range of laser welders covers all types of handheld laser welding.

Laser Welders

Laser Welders

Laser Welders

Laser Welders

Laser-welder.com.au specialises in hand held laser welders, because our sister company Deliver-Eze parcel letterboxes has demonstrated their massive benefits.

– Very high return on investment and rapid payback.

– Hand held laser welders are more flexible than CNC or robotic types

– No need for expensive jigging. Less setup than robotic welding.

– Super fast! Very high output per worker.

– Typically 4 times faster than TIG. 4 time$ cheaper!!

– No need for highly skilled TIG welders. Less skilled labour can be used.

– Less HAZ, weld stain, and no rework or finishing in most cases.

– Less fire risk. Almost no sparks or spatter.

– Far less consumables and argon gas required, due to much faster welding.

– No need to remove galvanising before welding.

They range from $14,800 to $17,800. We have fibre lasers from 1kw up to 2kw or 2000W, with 1500W being the sweet spot for performance vs cost. Our 1500W water cooled models are the best value on the market, at AU$14,800.00 (ex. GST) with free delivery in Melbourne.

Moving up to 2000W adds $3,000.

Our air cooled Lightwelder15 is AU$17,800 making it basically half the price of what the machinery sellers are charging. You will not beat our prices or service.

Although our lasers are much more efficient than the previous generation, cooling is the limiting factor for laser welder size and weight. The laser must be kept cool to avoid damaging the internals and reducing its life. Poorly designed laser welders get too hot in hot weather and have to be shut down, AKA run at a low duty cycle. This is the last thing you want in production!

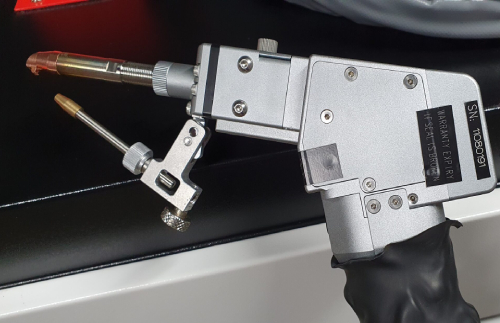

Our portable air cooled laser welder, Lightwelder15, achieves this in two light and compact ways. Firstly, reducing heat rejection by increasing efficiency through its 976nm input wavelength. Its effiency is at the top of the class at 42%. Secondly, by cooling the laser and also the welding head with a refrigerant loop and heat pump technology, like an air conditioner. Using latent heat of evaporation transfers heat very effectively. As a result, this 1.5 kiloWatt model can run all day at 35 degrees C, which is impressive.

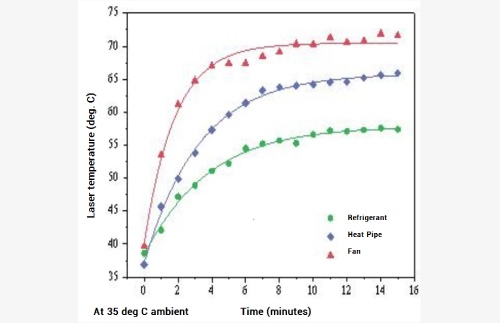

Competing IPG units (2-3x our price) use heat pipes, which can’t transfer heat as quickly as refrigerant pumping. Meanwhile Max (dearer and closer to 1300W than their advertised 1500W) uses fan cooling. The graph shows how our refrigerant system beats the others hands down. Note that running at high temperature greatly reduces laser life.

For a small cost premium over a water cooled unit, any business requiring portability should look seriously at our portable 1500W laser welder.