Fibre Laser Welding Glasses Fitover Green

$120.00 Ex. GST

These affordable, fitover type Fibre Laser Welding Glasses provide excellent eye protection during fibre laser welding and cleaning processes.

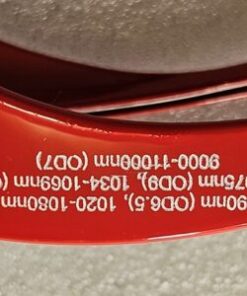

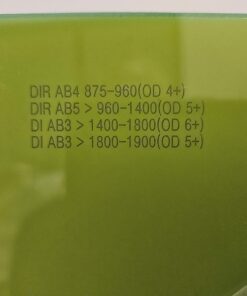

Fibre Laser Welding Glasses Fitover Green D LB6 for Spectacles

Great for fibre laser cleaning and welding. These are excellent value, high quality fibre laser glasses with 25% VLT (Visible Light Transmission). Suitable for wearing over spectacles. High protection for fibre lasers (approx. 1060 to 1080nm).

The comfortable green frame with 25% Visible Light Transmission marks them as dedicated for laser welding, so they won’t be mixed up with conventional safety glasses in the workshop.

These are the second best plastic lens glasses we have tested, offering great protection against harmful laser welding radiation. For fibre lasers they protect better than glasses costing twice as much, and other glasses with suspiciously higher markings (buyer beware). Very comfortable and light, they fit over almost all standard spectacle frames.

These can be used for cleaning also, where their 25% VLT dims the visibly bright light from ablating (burning away) coatings. For very bright ablation you should wear these under our laser welding helmet (which is auto darkening and adjustable for brightness).

With a stylish and ergonomic design, these fitover glasses ensure both safety and convenience, making them an essential accessory for all welders, including those requiring prescription eyewear in fibre laser welding environments.

IMPORTANT SAFETY NOTES: Must be worn under our laser welding helmet. These meet AS 13378.4 (EN 207) with protection level D LB6, but a 2kW laser welder requires around D LB8 to cover worst case reflections during welding, which our helmet provides. With kiloWatt level lasers a strong reflection at close range could quickly start penetrating ANY laser glasses. Note we have seen glass lenses shatter quickly under this condition, which reduces the protection to zero. To avoid such a dangerous scenario we use plastic lenses, which don’t shatter, and insist our laser welding helmet be worn over the glasses. After years of laser welding we believe this is the safest solution. It provides reduncancy in the event of operator errors or omissions, always leaving the operator with some protection. It’s the only way we weld. Don’t forget that anyone close to the welder must wear glasses and a helmet also, particularly a helper as they could receive a full reflection at close range.

Related products

Laser Safety

Laser Safety

Laser Safety